Solution for 1500V Inverter on Rooftop Appliance

2022-09-26 16:48

The application of systems using 1500V inverters on the rooftop is on the one hand the investor/EPC is under cost pressure to choose a lower investment and higher return solution to cope with the impact of the gradually declining PV tariff; on the other hand, it shows that the PV industry is gradually moving towards the digital era, and advanced PV technology is rapidly and widely applied to PV projects through perfect data model and practical evidence. In commercial and industrial distributed applications, 1500V inverters are increasingly being used on distributed rooftops.

1.Feasibility of PV system using 1500V inverters

The 1500V system has been adopted in a large number of utility-scale PV plants, with reliable and stable system operation. Some owners of high-voltage grid-connected commercial and industrial distributed projects have started to try the 1500V system, using 250kW inverters to realize high-voltage grid connection and meet the purpose of cost reduction and efficiency increase. In terms of economy, the system based on a 1500V high power string inverter reduces the overall LCOE by 7% through the application of higher voltage, higher power, higher DC/AC ratio, larger sub-array, and active safety technologies. In terms of safety, Goodwe's GW250K(N)-HT inverter is well-prepared for power plant safety operations. AFCI3.0 (Anti-DC Arcing), incorporating AI technology, has a 100% arc detection accuracy rate and a detection length of up to 200 meters, which can shut down the fault circuit within 500ms to protect the electrical safety of the DC side and prevent fires from occurring. It is also equipped with secondary lightning protection as standard to ensure the safe operation of the inverter in harsh environments. Various functions. Support PLC communication, saving communication cables; support PID prevention or repair function of PV modules to ensure that they always work in the best condition; SVG function, which can replace traditional SVG or SVC to compensate reactive power and eliminate harmonics in power plants; IV scanning and diagnostic technology, making PV operation and maintenance digital and intelligent.

2.Advantages of the 1500V system

Compared with the 1100V system, the voltage of AC and DC side increases, which has obvious advantages in improving the power generation efficiency of PV power plant system, reducing system loss, and construction cost.

(1) 1500V system has more strings, which saves DC cable cost; it supports PLC communication, which saves communication cable cost and thus reduces the system cost.

(2) At the same time, the voltage is increased, and the cable loss is further reduced, reducing line loss and increasing power generation.

(3) Maximum efficiency 99%, Europe efficiency 98.5%, maximum string current 20A, compatible with 210mm modules, 1.1 times long-term overload at 45℃, full load operation at 50℃. Maximize the efficiency of power generation and improve the yield.

(4) Overall IP66 protection, C5 anti-corrosion, no fuse, no wearing parts design, to ensure that the inverter can cope with a variety of harsh environments, stable and reliable.

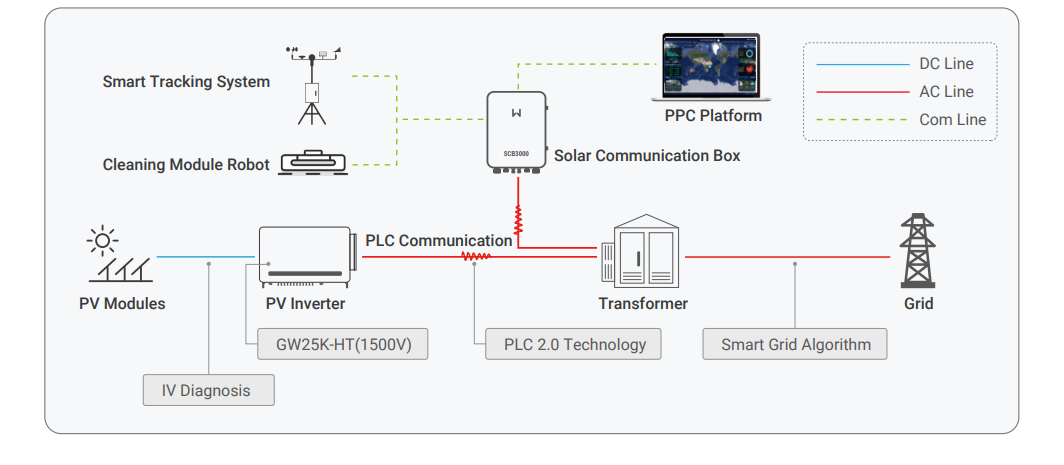

(5) Intelligent communication box SCB3000. realize intelligent networking, not only can access the inverter of PV area, but also can access various third-party equipment such as the monitoring and control devices of the transformer station, weather stations, smart meters, etc., so that the equipment status of PV area can be shown to the operation and maintenance monitoring platform.

(6) IV intelligent diagnosis, string current monitoring, rapid location of failure string, and give scientific maintenance advice, make the operation and maintenance of PV area digital, intelligent, and improve the efficiency and accuracy of operation and maintenance.

3.The design essentials of the 1500V system

(1) String design For a 1500V system, the inverter MPPT voltage tracking range is 500-1500Vdc, and the maximum input voltage is 1500Vdc. The DC input of the string should meet the open circuit voltage at the lowest temperature of the project site is less than the maximum DC voltage of the inverter, and the normal operating voltage meets the MPPT range of the inverter.

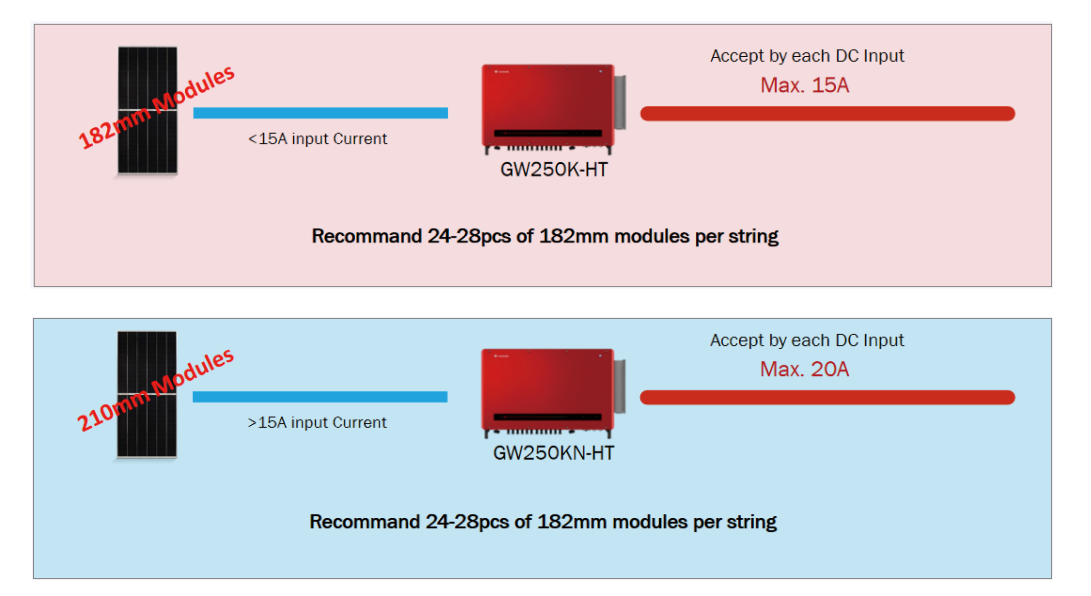

It can be calculated that if the 182mm module is used, each string can be connected to 24~28 pieces; if the 210mm module is used, each string can be connected to 32~36 pieces.

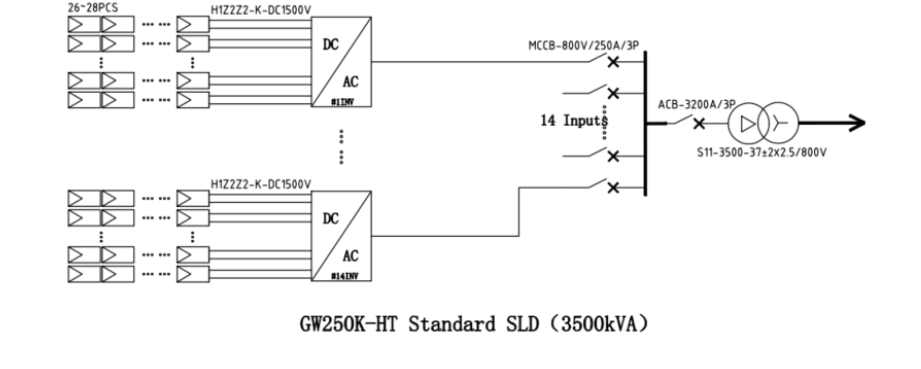

(2)Sub-array design generally, the 1500V system use 14 inverters with a 3500kVA transformer station combination is the most economical. MV transformer station low-voltage side rated voltage is 800V, high-voltage side rated voltage is 10kV or 35kV. Also can adapt to the following 3500kVA sub-array design scheme.

(3)Communication system design The inverters in the PV area adopt PLC (Power line communication). At the same time, the SCB3000 can also access various third-party devices such as the monitoring and control system of the MV transformer station, weather station, smart meter, etc. through RS485.

Conclusion

In the high-voltage grid-connected C&I projects, the 1500V system with its large arrays and high over-allocation characteristics, with leading technology and superb application experience, has undoubtedly become a powerful tool to reduce cost and increase efficiency in the current PV system, providing lower cost and revenue guarantee for distributed PV plants.

For more details, pls download the file to read the complete article.

Dear User,

Thank you for visiting our community. We would love to hear about your opinion - simply fill out and hit confirm. Thank you for your feedback!