MV Station-Reliable Support for Utility Station

2024-05-17 14:36

Background

With rapid global development, the demand for power supply continues to grow, especially for PV power generation, according to various organizations predicted that by 2030, the global capacity of PV power station will increase from 1,055GW in 2022 to 5,457GW, PV generation full-speed development is still the general trend.

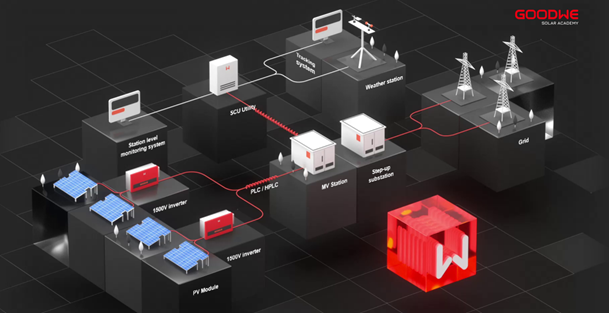

The PV station is mainly composed of PV modules, structures, inverters, MV stations, monitoring systems, cable accessories, etc. Comparing with traditional power stations, one big difference of PV station is that the planning and deployment are faster, with the increasing demand for PV station, flexible and reliable European type MV station become a popular choice.

European type MV station is a kind of closed power equipment, using standard 20 feet container as the enclosure, integrating transformers, RMU, LV swithgear, auxiliary transformer, protection devices and other power equipment inside, convenient for installation, compact structure, reliable performance, suitable for utility PV power station scenarios.

GoodWe to meet the market demand, launched GW9100K-MVS MV station, the capacity of transformer is up to 9152kVA, the maximum voltage in high voltage side can reach 40.5kV. The larger capacity, the lower LCOE, which not only meets the market demand, but also perfectly match GoodWe UT350kW series inverter, it can support up to 26 UT series inverters.

Figure 1 GW9100K-MVS

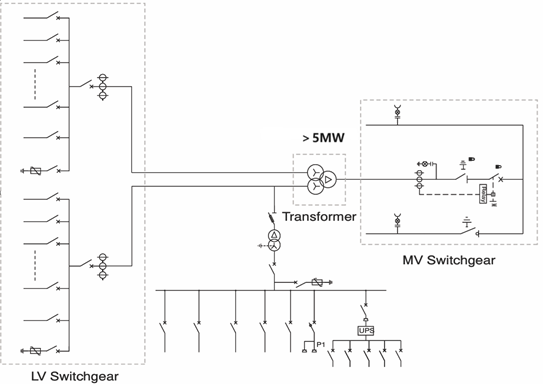

Figure 2 SLD of transformer with 2 LV winding

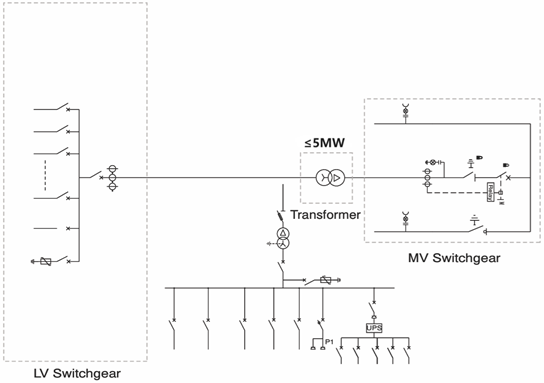

Figure 3 SLD of transformer with 1 LV winding

Features of GW9100K-MVS

1.Highly integrated

GoodWe MV station adopts the modular design principle, through the modular combination of various power equipment, like transformers, switchgear, auxiliary transformer, UPS, MCCB, protection devices and other power equipment, integrated in the standard 20-foot container, it can be easily transported and installed. In the meanwhile, it can be customized according to different requirements to meet the requirements of different application scenarios. This design improves the flexibility and adaptability of the system. The majority assembly and testing work is done in factory, greatly reduce the workload of on-site installation and commissioning, can be built in a short time, quickly put into use, improve the reliability and stability of the equipment.

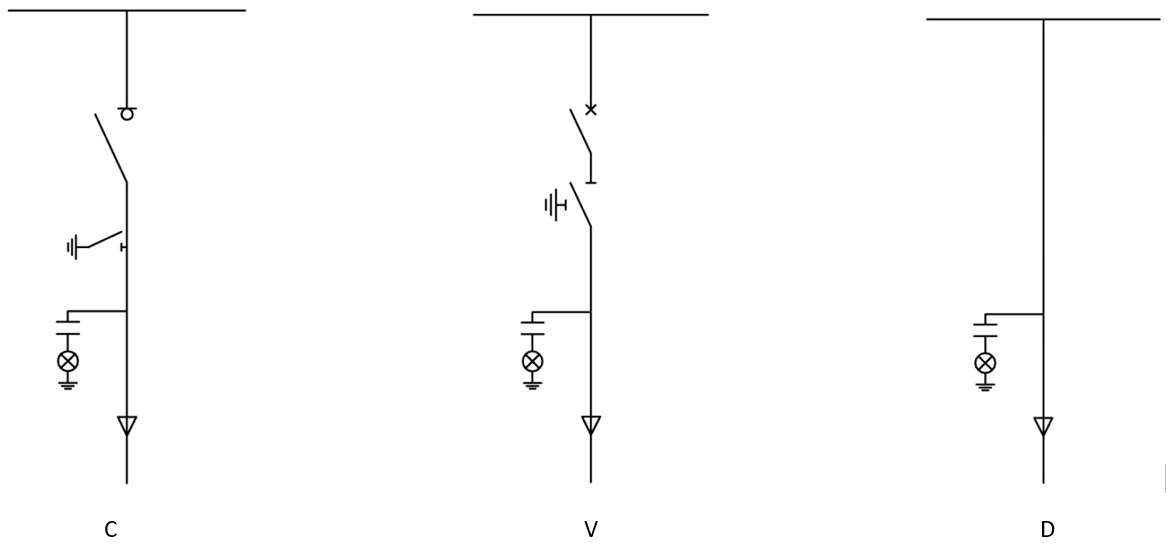

1.1 MV design

The MV side design adopts the gas-insulated ring main unit(RMU). According to different application scenarios, the RMU can be flexible, we can configure CVC, DVC, CV, DV etc.

C- Cable load break switch

V- Vacuum circuit breaker

D- Direct connection

At the same time, it is also equipped with a certain capacity of auxiliary transformers and UPS, which are used to supply power to the secondary circuit of the MV station, lighting, heating, air conditioning cooling and other devices.

Here’s a system view of a sample station

Figure 4 system view of a sample station

1.2 Transformer design

The transformer is an oil-immersed with no-load tap changer with a European efficiency of 99.606% (meeting the Tier 2 energy efficiency requirements), using Dy11 or Dy11y11 verctor group. The capacity can be flexible, the maximum can be 9152kVA. And for the needs of different scenarios, the transformer can provide mineral oil and vegetable oil two kinds of insulation and heat dissipation media, natural air cooling. The main parameters are as follows:

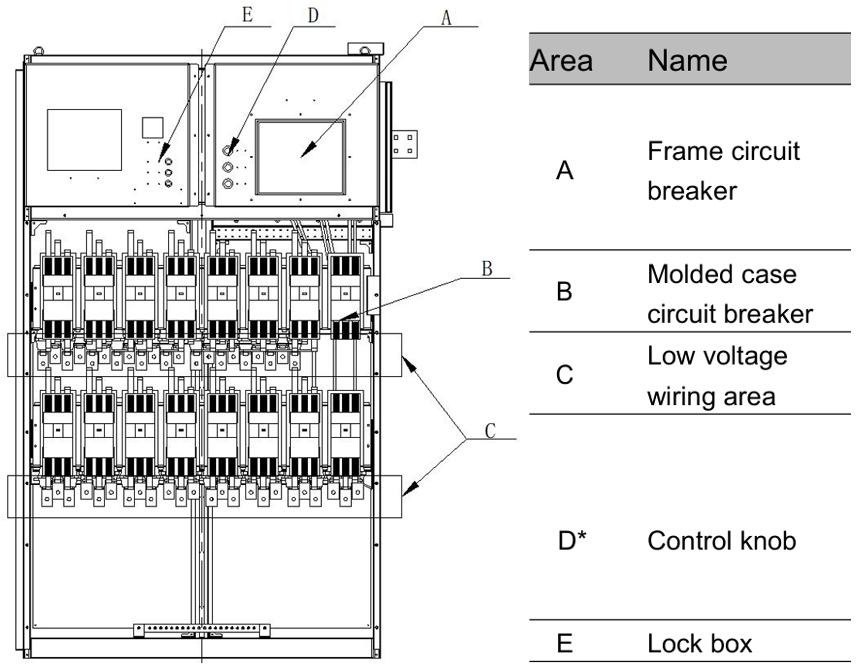

1.3 LV design

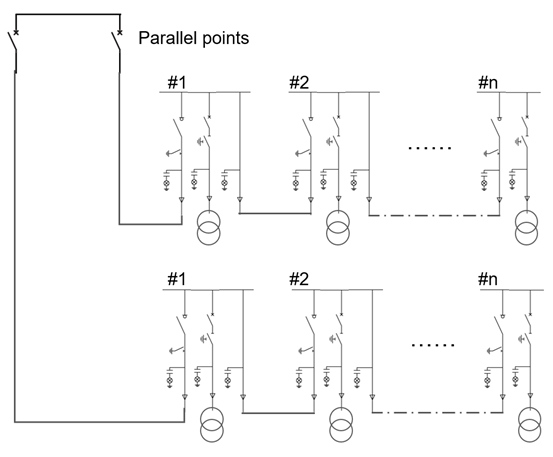

There are two LV rooms for connecting to inverters. The LV room is equipped with MCCBs for connection with the inverter to ensure that each inverter is an independent loop and does not interfere with each other.

Figure 5 LV design

1.4 Protection and control design

GoodWe MV station not only has the function of measurement and control, it is also equipped with a complete relay protection function to protect the electrical safety of the MV station itself and the the equipment connected to it. It includes overcurrent protection, overvoltage protection, undervoltage protection, overload protection, over-frequency protection, underfrequency protection etc. For the transformer itself, it is equipped with gas protection, oil temperature, winding temperature protection etc. Protection setting can be adjusted flexibly according to project requirements. These protection functions enable the MV station to respond in time and take measures under various abnormal conditions to ensure the safe and stable operation of the power system and equipment. The design and implementation of protection function is an important part of MV station, which can effectively protect the equipment and extend the life of the equipment. Fully ensure the safety of equipment operation to prevent the expansion of accidents.

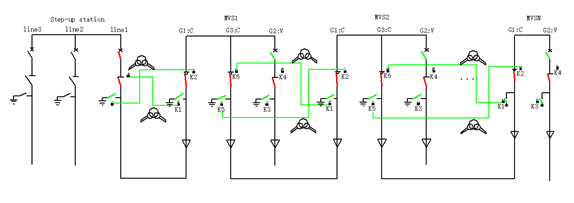

The MV station is equipped with a mechanical interlocking device, which can effectively prevent mis-operation , resulting in electrical accidents, and ensure equipment and personal safety. We also providing the interlocking between MV stations, as shown in below figure.

Figure 6 Interlocking between MVS

1.5 Communication design

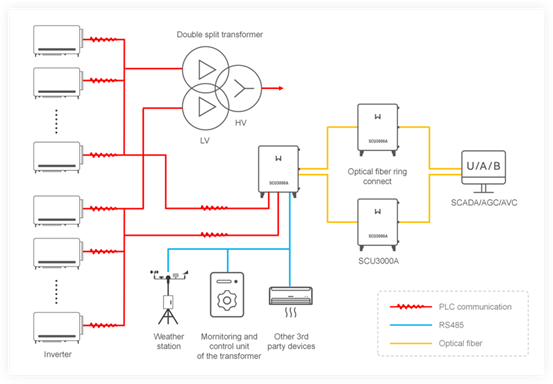

GoodWe MVS integrates the overall communication solution of PV area, supporting GoodWe SCU3000 series communication box. This communication box integrates a variety of communication methods and communication protocols. It can access the inverter data through the PLC, and also provides a multi-channel RS485 communication interface to facilitate access to various equipment in the PV area. At the same time, it also has optical fiber ring network switches and optical fiber welding boxes, which can complete the needs of optical fiber communication in the PV area, and provide one-stop communication solutions in the PV area.

Figure 7 System design of communication

Ps: For more details, pls download the file below.

Dear User,

Thank you for visiting our community. We would love to hear about your opinion - simply fill out and hit confirm. Thank you for your feedback!